Robotics is no longer a futuristic concept; it’s transforming workplaces across various industries today. From manufacturing floors to office environments, robots are enhancing productivity, efficiency, and safety. Understanding how robotics is changing the workplace can help you stay ahead in a rapidly evolving job market. Explore these 18 groundbreaking robotics innovations that are reshaping the future of work.

Collaborative Robots (Cobots)

Collaborative robots, or cobots, are designed to work alongside human workers, enhancing productivity and safety. Unlike traditional industrial robots, cobots are equipped with sensors and advanced software to detect and respond to human presence. This makes them ideal for tasks requiring close human-robot interaction, such as assembly lines or material handling.

Cobots can be easily programmed and reprogrammed, allowing for greater flexibility in the workplace. They can perform repetitive and strenuous tasks, reducing the risk of injury for human workers. As a result, companies are seeing increased efficiency and reduced operational costs.

Automated Guided Vehicles (AGVs)

Automated guided vehicles (AGVs) are used in warehouses and factories to transport materials without human intervention. These vehicles follow predefined paths using sensors, magnets, or lasers, ensuring precise and efficient movement of goods. AGVs help streamline logistics operations, reducing the need for manual labor and minimizing errors.

AGVs can operate 24/7, significantly boosting productivity and throughput. They are particularly useful in environments where materials need to be moved frequently and reliably. By automating material transport, companies can optimize their supply chain and reduce costs.

Robotic Process Automation (RPA)

Robotic process automation (RPA) involves using software robots to automate repetitive, rule-based tasks in business processes. This technology is widely used in finance, human resources, and customer service to handle tasks such as data entry, payroll processing, and customer inquiries. RPA helps organizations achieve higher accuracy and speed in their operations.

Implementing RPA reduces the workload on employees, allowing them to focus on more strategic and value-added activities. It also improves compliance and reduces the risk of human error. Companies adopting RPA can achieve significant cost savings and operational efficiency.

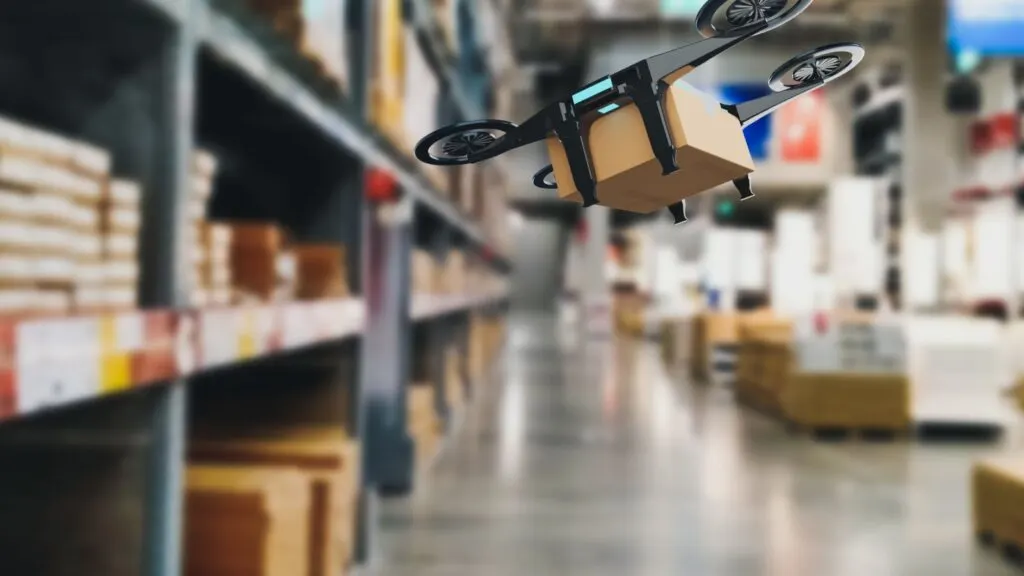

Drones For Inventory Management

Drones are increasingly being used in warehouses for inventory management and stocktaking. Equipped with cameras and sensors, drones can quickly scan and record inventory data, providing real-time updates. This reduces the need for manual stock checks, saving time and improving accuracy.

Drones can access hard-to-reach areas in large warehouses, ensuring a more comprehensive inventory count. They also help reduce labor costs and minimize disruptions to daily operations. By leveraging drone technology, businesses can maintain better control over their inventory and enhance overall supply chain efficiency.

Exoskeletons For Worker Assistance

Exoskeletons are wearable robotic devices that assist workers in physically demanding tasks. These devices support and augment human movement, reducing strain and fatigue. Exoskeletons are particularly beneficial in industries such as construction, manufacturing, and logistics, where heavy lifting and repetitive tasks are common.

With exoskeletons, workers can perform tasks with greater ease and less risk of injury. This not only improves worker safety and well-being but also enhances productivity. Companies adopting exoskeleton technology can expect to see a decrease in workplace injuries and an increase in efficiency.

Autonomous Mobile Robots (AMRs)

Autonomous mobile robots (AMRs) navigate environments independently using sensors and artificial intelligence. Unlike AGVs, AMRs do not require predefined paths and can adapt to changing surroundings. This makes them ideal for dynamic and complex environments such as warehouses and distribution centers.

AMRs can perform tasks such as picking, sorting, and transporting items, significantly improving operational efficiency. They can work collaboratively with human workers, further enhancing productivity. As AMR technology advances, more industries are expected to adopt these versatile robots.

Robotic Welding Systems

Robotic welding systems are used in manufacturing to perform precise and consistent welds. These robots are programmed to handle various welding tasks, improving speed and accuracy. Robotic welding is particularly useful in the automotive and aerospace industries, where high-quality welds are critical.

By automating the welding process, companies can achieve higher production rates and better product quality. Robotic welding also reduces the risk of human error and enhances worker safety. As a result, manufacturers can enjoy increased efficiency and lower production costs.

Cleaning And Sanitation Robots

Cleaning and sanitation robots are becoming essential in maintaining hygiene in workplaces. These robots can autonomously clean floors, disinfect surfaces, and even sanitize the air. They are particularly useful in healthcare facilities, offices, and public spaces where cleanliness is paramount.

Using cleaning robots, businesses can ensure a higher standard of hygiene with minimal human intervention. These robots can operate around the clock, providing consistent and thorough cleaning. This not only improves workplace safety but also reduces the spread of illnesses.

Inspection Robots

Inspection robots are used to monitor and assess the condition of infrastructure and equipment. Equipped with cameras, sensors, and advanced software, these robots can detect defects, corrosion, and other issues. Inspection robots are commonly used in industries such as oil and gas, power generation, and construction.

By automating inspections, companies can improve the accuracy and frequency of their assessments. This helps in the early detection of problems, reducing the risk of costly failures and downtime. Inspection robots also enhance worker safety by eliminating the need for manual inspections in hazardous environments.

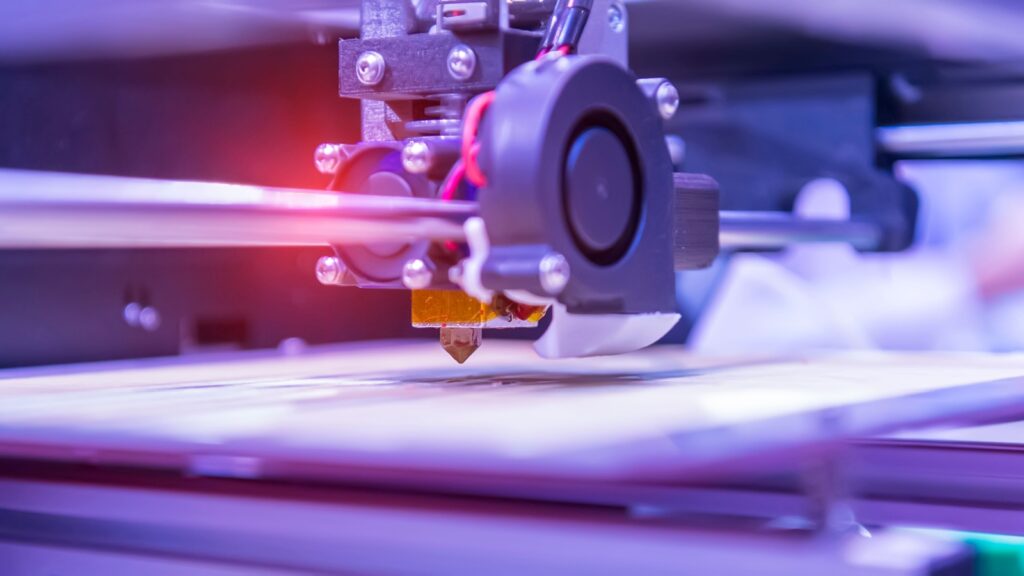

3D Printing Robots

3D printing robots are revolutionizing manufacturing by enabling the creation of complex and customized parts. These robots use additive manufacturing techniques to build objects layer by layer from digital models. 3D printing robots are used in various industries, including aerospace, automotive, and healthcare.

With 3D printing robots, companies can reduce production times and costs, as well as minimize material waste. This technology also allows for greater design flexibility and rapid prototyping. By adopting 3D printing robots, businesses can stay competitive and innovate more effectively.

Robotic Palletizers

Robotic palletizers are used to automate the process of stacking and organizing products on pallets. These robots can handle various product sizes and weights, improving the efficiency of packaging and shipping operations. Robotic palletizers are commonly used in industries such as food and beverage, pharmaceuticals, and consumer goods.

By using robotic palletizers, companies can increase the speed and accuracy of their palletizing processes. This reduces labor costs and minimizes the risk of product damage. Robotic palletizers also improve worker safety by eliminating the need for manual lifting and stacking.

Medical Robots

Medical robots are transforming healthcare by assisting in surgeries, diagnostics, and patient care. These robots can perform precise and minimally invasive procedures, improving patient outcomes. Medical robots are also used for tasks such as medication dispensing and patient monitoring.

By integrating medical robots, healthcare providers can enhance the quality and efficiency of their services. These robots reduce the workload on medical staff and allow for more accurate diagnoses and treatments. As medical robotics technology advances, more healthcare facilities are expected to adopt these innovations.

Retail Robots

Retail robots are used in stores to assist with inventory management, customer service, and store maintenance. These robots can scan shelves, restock products, and guide customers to their desired items. Retail robots help improve the shopping experience and streamline store operations.

By using retail robots, stores can maintain better control over their inventory and reduce stockouts. These robots also free up staff to focus on more complex tasks, enhancing overall customer service. Retail robots are becoming an integral part of modern retail environments, driving efficiency and customer satisfaction.

Construction Robots

Construction robots are changing the way buildings and infrastructure are built. These robots can perform tasks such as bricklaying, concrete pouring, and demolition. Construction robots improve the speed, accuracy, and safety of construction projects.

By using construction robots, companies can reduce labor costs and minimize the risk of workplace accidents. These robots also ensure consistent and high-quality work, improving project outcomes. As construction technology advances, more projects are expected to incorporate robotic solutions.

Robotic Baristas And Chefs

Robotic baristas and chefs are transforming the food and beverage industry by automating the preparation and serving of food and drinks. These robots can brew coffee, cook meals, and serve customers with precision and speed. Robotic baristas and chefs help improve service consistency and reduce wait times.

By using robotic baristas and chefs, restaurants and cafes can increase their efficiency and reduce labor costs. These robots also enhance the dining experience by providing high-quality and personalized service. As the demand for automation grows, more food and beverage establishments are expected to adopt robotic solutions.

Security Robots

Security robots are used to monitor and patrol premises, enhancing the safety and security of workplaces. These robots are equipped with cameras, sensors, and AI technology to detect and respond to potential threats. Security robots are commonly used in offices, warehouses, and public spaces.

By using security robots, companies can improve their security measures without increasing labor costs. These robots provide continuous surveillance and can respond quickly to incidents. Security robots also reduce the risk of human error and enhance overall safety.

Robotic Receptionists

Robotic receptionists are used to greet visitors, manage appointments, and provide information in office environments. These robots can interact with people using natural language processing and AI technology. Robotic receptionists help improve front desk operations and enhance the visitor experience.

By using robotic receptionists, companies can reduce the workload on human staff and improve efficiency. These robots provide consistent and accurate service, enhancing overall customer satisfaction. Robotic receptionists are becoming a popular choice for modern offices, driving innovation and efficiency.

Agricultural Robots

Agricultural robots are transforming farming by automating planting, harvesting, and crop monitoring tasks. These robots use advanced sensors and AI technology to optimize farming operations and improve crop yields. Agricultural robots help reduce labor costs and increase the efficiency of farming practices.

Farmers can achieve higher productivity and better resource management by using agricultural robots. These robots also enable precision farming, reducing the environmental impact of agriculture. As the demand for sustainable farming grows, more agricultural operations are expected to adopt robotic solutions.